Materials:

Silicon Polyethylene Silicon Lubricant

3" Long Screws, Drywall Screws, Zip Screws

Tools:

Cordless Drill Screwdriver Nutdrivers Flashlight

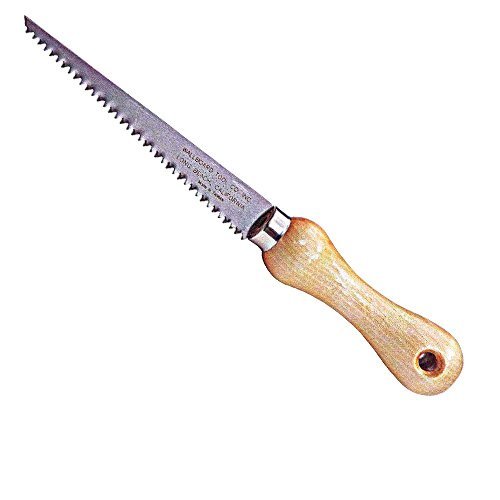

Hammer Caulk gun Drywall saw

If you are having ticking noises in your basement most likely, they are coming from the hangers!

If you did not finish your basement off yet then it would be relatively simple to fix. Also, if in your basement you have a drop ceiling then consider yourself as a lucky one, the most difficult task would be if your ductwork is covered with the drywall!

Let’s start in the basement with the drywall on.

First of all, you have to locate where the noise is coming from. Don’t even waste your time on that! When supply duct contracting or expending it’s rubbing against the hangers and makes the ticking noise! So, where those bad hangers are? The first pair of hangers should be right at the duct’s end or maybe just a foot away. Find where, approximately, the supply duct ends and knock on the drywall. Find where drop’s member (I’m intentionally naming piece of 2 x 4 as a drop’s member because in your case it could be a metal stud or something else) ends and make a pilot hole by using a screwdriver and a hammer. Don’t use a drywall saw to make a pilot hole, because if accidentally you will hit a drop’s member you may bend it out:

- Shove a drywall saw in the pilot hole and cut it until you reach the next drop’s member

- Cut it in the opposite direction

- Make an opening big enough so you are able to work inside

- Unscrew the hanger, use a cordless drill with a ¼” magnetic socket or a nutdriver for that, bend the hanger up and look at it

In order to fix the problem you have to put some silicon right on the black spots. Use only permanently flexible type of silicon, which is remain permanently flexible and will resolve your issue forever! After you cover up all the suspicious spots with silicon, screw the hanger back on.

However, some of my customers could not find this kind of silicon. So, if you are also having difficulties in obtaining the permanently flexible silicon use a piece of the polyethylene. For the better result use only thick one so it lasts longer. Cut a piece of the polyethylene, put it between the hanger and the duct and screw the hanger back on.

In some instances supply and return ductwork is hung too close to each other or it is too close to the I-beam, or to the drop’s members. In cases like this, you may use a hammer and a screwdriver to knock out a screw or maybe just pry the hanger away. Once it is done you can use a brush to bring some silicone in, or you can use a silicone-based lubricant.

After you have been done with the first hanger, find the second hanger on another side of the duct. Once the first pair of hangers was found and taken care of, you have to find the second one. Usually the last piece of duct is shorter than pieces before it, and it could be only one set of hangers taking care of this particular piece, but in general a piece of duct is 8’ long and the hangers could be found 1’ away from the each end. Sometimes there are pieces of duct 4’ long, this type of ductwork usually has only one pair of hangers and it’s difficult to be certain where they are. However, you can try to see them from the last opening in the drywall you just cut out.

Besides hangers using to hang the duct, there are some hangers that are using for the pipes. They also can be source for the ticking noise and use of the silicon will eliminate that.

In the same basement, one of the heat runs was making a ticking noise.

When I cut the drywall there was not any hangers but it was a lose

connection between two 6” pipes. Those pipes were moving against each

other and making the noise. It was enough just to lift the pipes up and

drive one more ½” zip screw, the noise is gone.

In the same basement, one of the heat runs was making a ticking noise.

When I cut the drywall there was not any hangers but it was a lose

connection between two 6” pipes. Those pipes were moving against each

other and making the noise. It was enough just to lift the pipes up and

drive one more ½” zip screw, the noise is gone.As you can see in the picture above in that basement were more than enough to fix only six hangers.

However, if your ductwork is open, just unscrew all the hangers one by one on all ductwork, supply and return, look for the black spots and fix them.

Once all hangers are done there could be more spots making the ticking noise, but it will be easier for you to find them, because there won’t be so many of them left, and now you know how to identify them – just look for the black spots.

If after you have been done there are still some places in your basement, which are making the noise, take pictures of the spots and send them to me.

Now I would like to introduce you a simple technique how to fix the holes in the drywall without too much trouble!

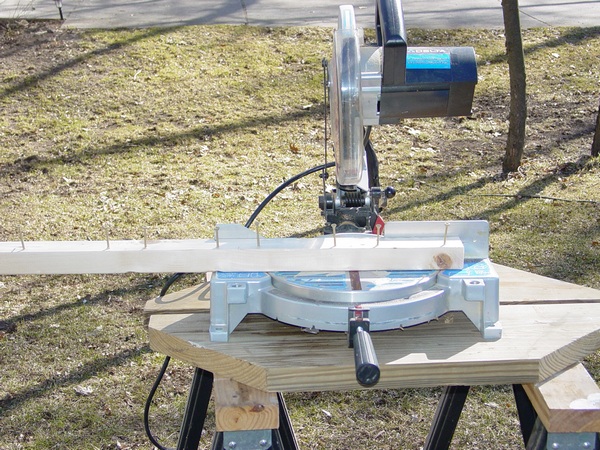

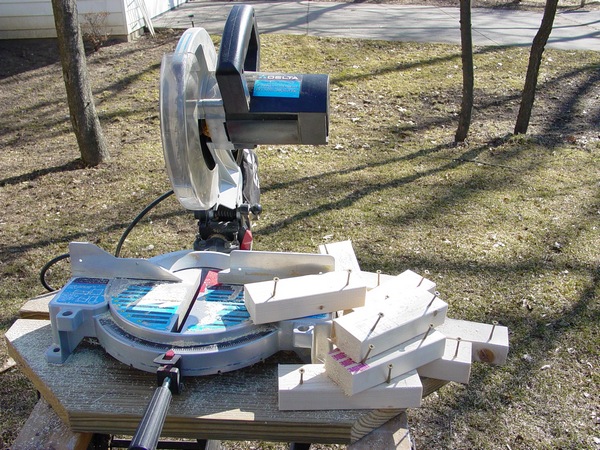

Buy a 2 x 3 stud (only $1.75 a piece) and start two screws for each piece necessary for the drywall. Cut those pieces with the flip-over saw and screw them to the drop’s members. Screw pieces of the drywall you just cut out, tape, send and paint them.

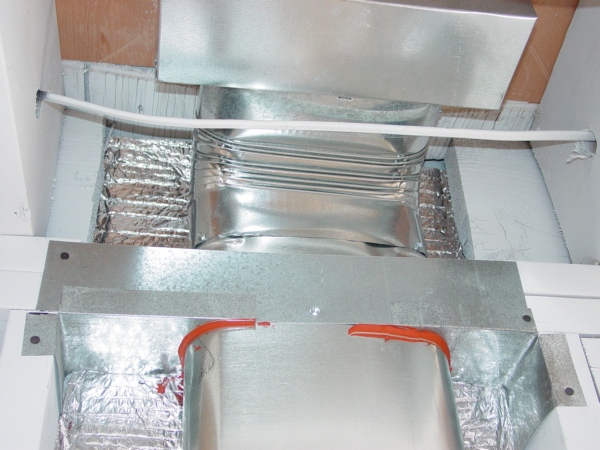

Some

of my customers have supply duct fastened tight to the joists. As you

can see in this picture a heating contractor screwed the duct from the

side up to the joist. Such installation is illegal because it against

code. Of course you can try to unscrew screws just a little bit, bring

the duct down away from the joists, but better check out your local code

in the code enforcement office and make your heating contractor to fix

it free of charge.

Some

of my customers have supply duct fastened tight to the joists. As you

can see in this picture a heating contractor screwed the duct from the

side up to the joist. Such installation is illegal because it against

code. Of course you can try to unscrew screws just a little bit, bring

the duct down away from the joists, but better check out your local code

in the code enforcement office and make your heating contractor to fix

it free of charge.If you are having a ticking noise in the walls, it can be because the oval stack is rubbing against

the rough strap at the top, floor angle at the bottom or it is touching the house wood frame. Also, noise can be transmitted from the basement. It is not difficult to understand the nature of the noise:

- If you hear a ticking noise with the metal sound in it, it is definitely coming from the metal parts, otherwise it's coming from the wood frame

Before you start cutting the drywall, try to find where the noise is coming from. If it’s coming from the top or from the bottom try to fix it with the long screws first – it’s always easier to repair a screw hole than a piece of drywall!

As you can see in the pictures above

there should be a rough strap 3 ½” wide at the top, but at the bottom

you can screw it directly to the base molding. Some heating contractors

are using floor angles at the top also, so you have to be aware that they are only 1 ½” wide.

As you can see in the pictures above

there should be a rough strap 3 ½” wide at the top, but at the bottom

you can screw it directly to the base molding. Some heating contractors

are using floor angles at the top also, so you have to be aware that they are only 1 ½” wide.If you have a crown molding at the top of your wall you are still able to screw an oval stack to it:

- Predrill a hole with a drill bit. Size of this drill bit should match the screw’s size

- Use another drill bit big enough to hide the screw’s head

- Screw an oval stack to the crown molding and fix the holes with the sheet rock joint compound.

Another source of the ticking noise are the B-vent pipes.

As you can see in the pictures above, only source of noise can be in the places where the pipe is passing through the floor or to the attic in the chase and it is touching a firestop. The best solution in this case would be just to push pipe away from the firestop and fill the gap with the silicone. This kind of silicon is rated for 400* F and it is safe to use. If you live in a ranch, it is going to be the best solution. However, in the colonial you may need an access to the firestop between the first and the second floors.

Another most unlikely source of the noise could be if the B-vent pipes were not thoroughly attached to each other. In this case, you also need an access to them through the drywall and you can screw them together at the joint. While doing that try not to penetrate with the screw through the inner aluminum pipe and it would be better instead of ½” long zip screws use ¼” long ones. Fill the gap with the silicone.

Also, the noise could come from the duct laying uninsulated on the rafters. In this case you have to lift the duct up and shove some insulation in between, insulate thoroughly afterwards.

In the case of the PVC and copper pipes, you also have to look for the black spots. Normally they do not make any noises if a heating or plumbing contractor hang them right.

The copper pipes usually are making noises when they are inside the walls, so you have no choice, but cut the drywall out.

In the rare case when a PVC concentric is making a ticking noise you have to apply some silicon everywhere where concentric’ cap is touching the outer pipe.

That is it, I hope that I have answered all your questions, if not, please ask them on this page.

Good article. I have a problem with duct ticking. Very annoying. I try these solutions this weekend.

ReplyDeleteYa, i had this in a new house, put up with it for 2 months, it would wake me up.

ReplyDeleteAll kinds of theories from all my "handi guy consultants, oil canning,long duct expansion, no solution just live with it, don't run heater at night (ya right) etc"

I listened with a stethoscope from above floor, measured, went below to drywall, found joists, made a small hole in drywall, and installed a small rubber washer at the hanger, just one side. Nailed it perfectly! complete success, minor time, minor repair work. Prior owner probably lived with this for 25 years, totally unnecessary.